If you’ve been following out Blogs, events or webinars. You’ll know that we understand production scheduling well and have created a scheduling package designed for manufacturers to improve their throughput.

The first dimension or view is scheduling the production floor. This is using our standard drag and drop scheduler. It does the basics in terms of displaying the load against the capacity. Allowing you to drag and drop forwards or backwards or to different work stations.

The second dimension is allowing the plant manager or program manager to see all of the jobs in a GANTT chart view. This allows him to see whether his jobs are going to be on time, when they will complete and where the bottle necks are.

The third dimension was a view from the shop floor, a graphical display of all of the jobs in jeopardy, with drill down to the statistics and progress of each job including a dispatch list that sorts and organizes jobs in an electronic kan-ban system. Driven initially from the production schedule but effectively pulled through by the operators scanning or clocking on to the jobs.

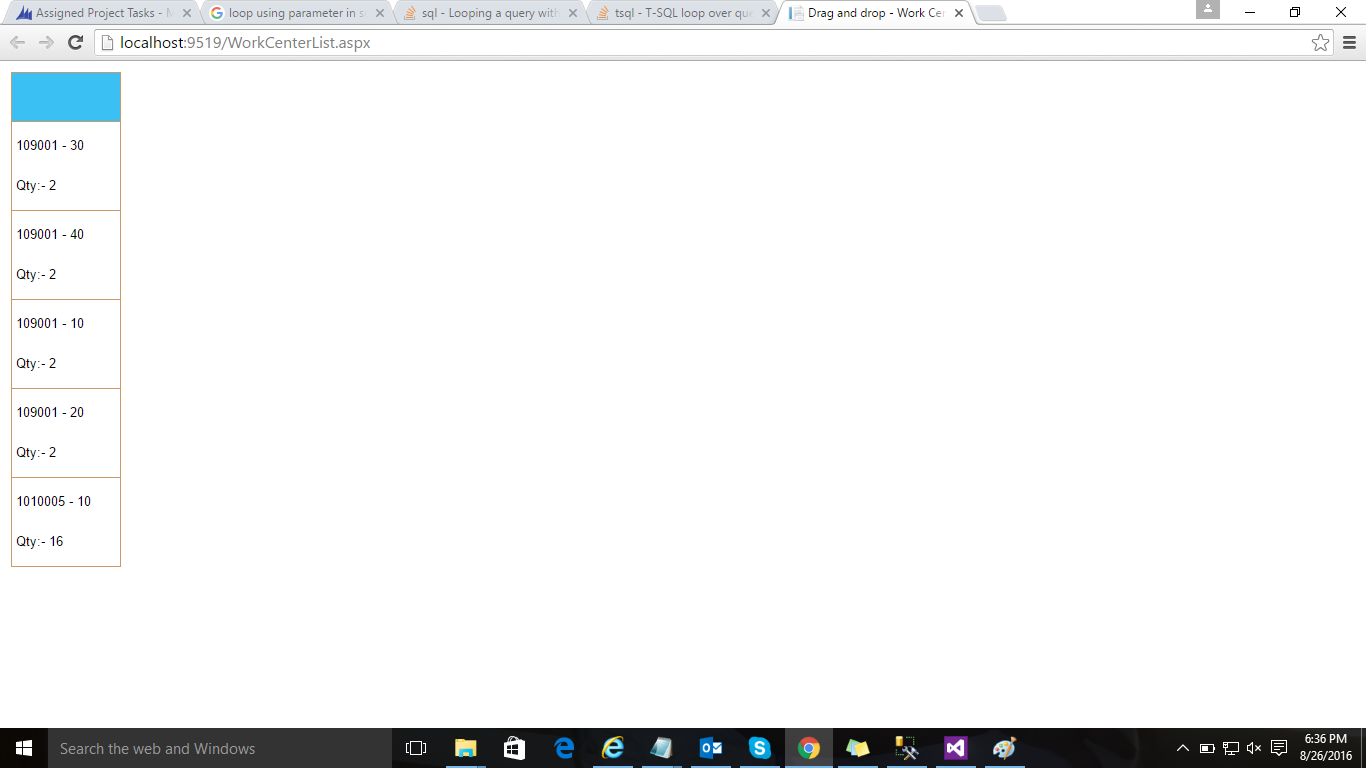

Now Vox ISM is ready to enter the 4th dimension of scheduling. The vision – shown below is an interactive dispatch list designed for your tablet or phone that allows the operator to ‘fine-tune’ the schedule. When completed (about 1 month) he will be able to drag and drop production orders from machine to machine and change the sequence. The idea is to display the entire production floor and status of all of the active jobs on 1 page.

When I was a production scheduler – I found it almost impossible to keep up with the changes on the shop floor. Furthermore because I didn’t work on the shop floor I didn’t understand how the operators would think. Optimizing production by size, jig, tooling, space, colour, setups….way more things than I could possibly know just by staring at numbers. Eventually I gave up on the vision of running an electronic production schedule because of these 2 reasons and adopted a methodology that I called ‘Black-box’ scheduling. This meant that I figured out the overall load vs. capacity for the shop, the throughput and on-time delivery, then only provided 3 days of production to the operators in what I called my ‘frozen’ period’. This worked quite well because I went from running the schedule and fiddling with it every 5 minutes and re-jigging every 4 hours to allowing the supervisor to work however he pleased, in whatever sequence he desired within the 3 days. So long as he was able to complete the given work in the time period, it didn’t matter. For changes, exceptions and priority changes, we just handled them manually….in red-ink. Simple and effective, and it allowed me to spend more time on the production floor, helping to move product through the shop.

So bringing it back to 2016, VoxISM will now have a production schedule tool designed specifically for the supervisor. Allowing him to apply the finishing touches to the schedule. In the subsequent releases of this product I hope to provide annotations, twitter like following, lag time or tack-time calculations and more.

So although it could be an easy tool for a barber-shop or pizza place, my desire is that this will fill the gap for production supervisors.

Happy scheduling everyone.

Mike Fontaine