Vox ISM would like to introduce its customers to FreePoint Technologies Inc.

Vox ISM would like to introduce its customers to FreePoint Technologies Inc.

FreePoint took the simple notion that you can’t improve what you don’t measure. In order to increase productivity for their customers they built monitoring technologies that interface to manufacturing equipment. This allows them to provide data in real-time to management and operators alike. Thus empowering organizations to improve productivity and maximize ROI.

Machine Tool Shop: Increase Productivity Case Study

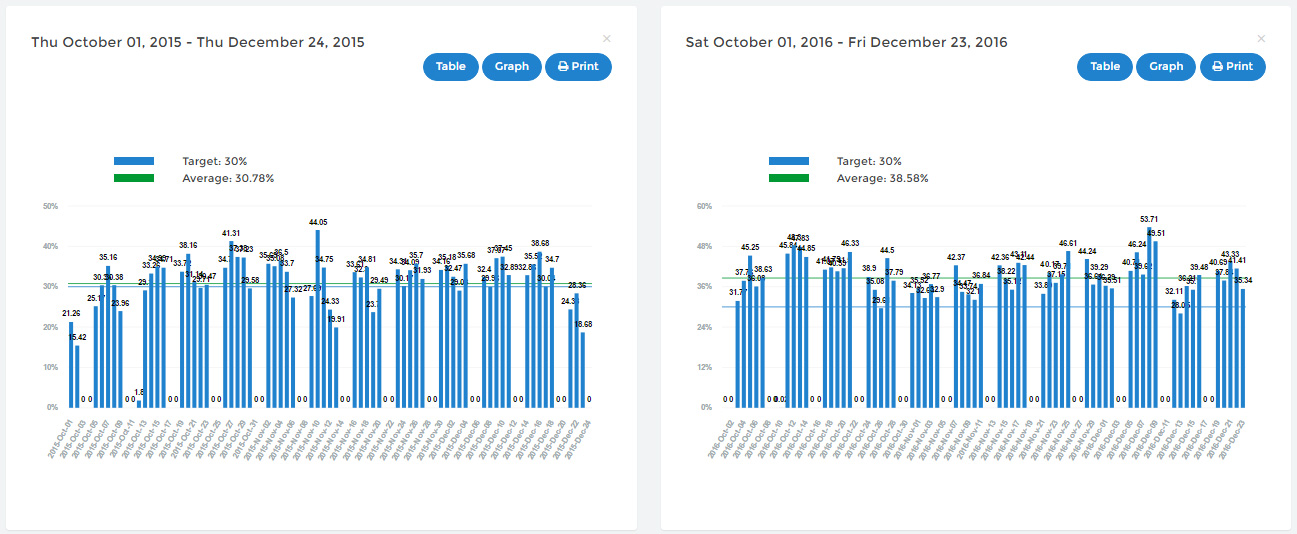

The customer is an Ontario-based machine tool shop. All of the company’s orders are for custom, single unit production. The following figures and study focus on their 6 most critical machines. To establish a baseline for comparison, the chart below shows the operating time for the mills for the period of October 1 to December 23 for 2015 and 2016 on a 24 hour X 5 basis.

In 2015, the average spindle time was 30.78% and for the same period in 2016, the average was 38.58%. This equates to an increase of 562 minutes, or 9.4 hours of additional utilization per week, per machine, or 1.2 extra shifts per week per machine. This represents a 25% increase over the same period last year.

Calculated net benefit:

The net improvement achieved in the operation of the mills in 2016 would be 141% of the cost of one full time operator for one shift. Assuming one full time operator costs the company $100K (all in cost), the net cost benefit would be $141K. Or looked at another way, if one hour of machine time generates $80 in revenue, the added revenue created equals 9.4hrs X 6 machines X 52 weeks X $80 = $234,624.

….

To read the full case study and learn more about FreePoint Technologies Inc. head over to their website www.getfreepoint.com

Case Study: Click here.