Advanced Manufacturing and the Injection Molding Industry

To draw an analogy to Marshall McLuhan (the medium is the message), the future of advanced manufacturing in the injection molding industry will be defined as much by the technology used to make a product as by the technology inherent in the product. The purpose of this article is to provide insight into what is available and possible with modern information systems. The future end goal is to provide a closed-loop system with the end result of improving the cycle-time and quality of the part.

Vox ISM doesn’t profess to be an expert in the long list of production technologies—CAD, CAE, CAM for design; high performance computing (HPC) for modeling, simulation and analysis; advanced robotics, additive manufacturing and other intelligent systems for production; but we do know how to connect and use information technologies to coordinate it all using Microsoft Dynamics 365.

If you are a member of CAMM or APMA you might have heard of our company. Vox ISM is working in a collaborative effort with the mold makers and injection molding industry in Windsor to help redefine manufacturing excellence.

The Microsoft Dynamics platform is modern with easy to create, built in web-service tools that connect to a variety of software systems today.

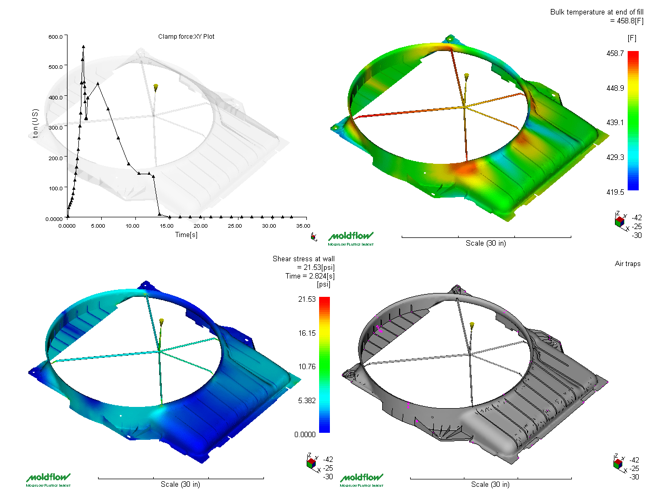

For instance in this excellent article: How to predict problems in injection molding, SolidWorks has created simulation software that can predict air gaps, heat, and stress.

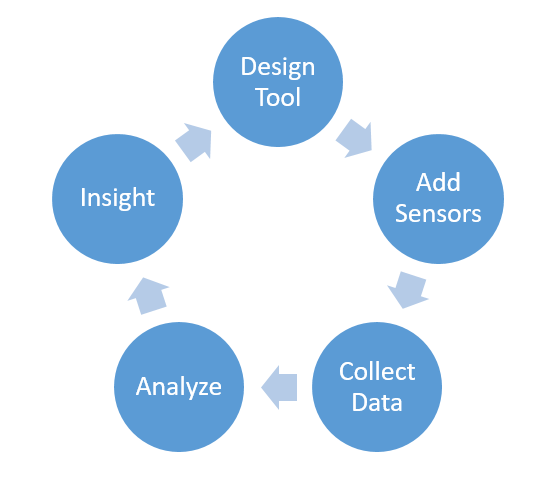

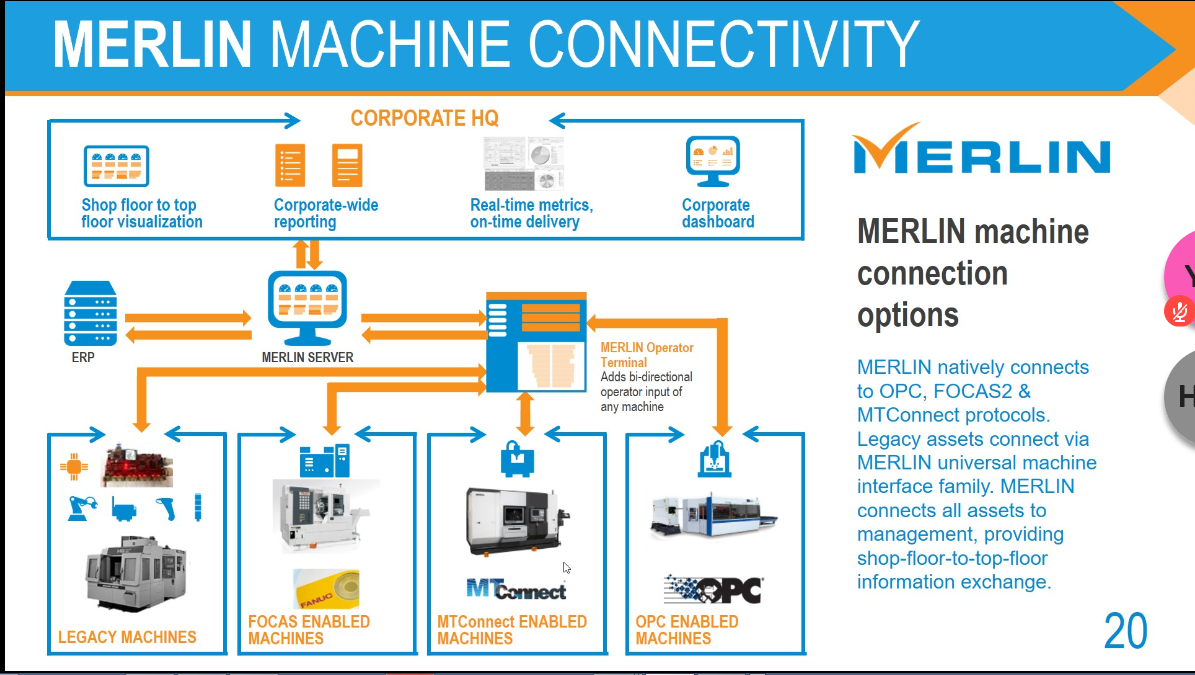

This is a great start to predicting how a tool might perform, but what if you were to connect sensors to the mold and then connect the sensors to the PLC using a MES (Manufacturing Execution System).

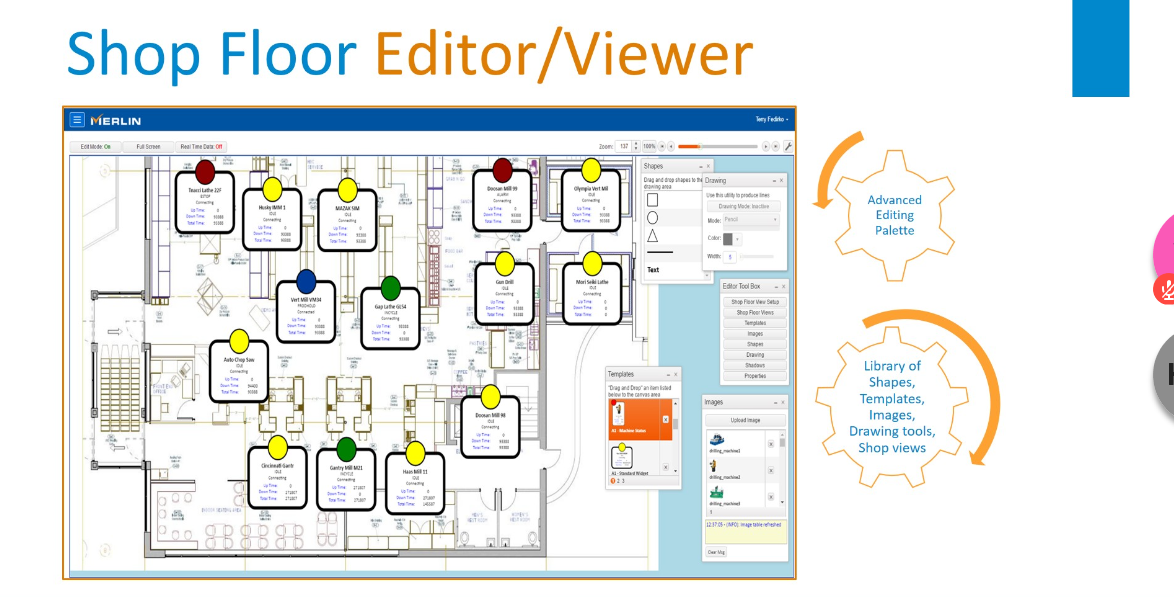

All of this is possible with low-end, mid-range and high end software packages that can connect to both your machines and your business system. Below is an example of what is possible using once of these systems.

Once we have collected real-time information, it can be monitored and controlled using the IOT Azure Hub, then automatically analyzed with Azure machine based learning. We are currently using machine based learning to predict machine download and therefore suggest preventative maintenance, but repetitive, real-time data-analysis not only provides instantaneous R&R Anova studies using our advanced quality system, but also a completing a feed-back loop to the manufacturer to improve his tool and increase the speed and quality.

Come join us on March 7th for a short webinar on how all of the technology can work together and how Vox is not just a software vendor but the keystone in something greater that is happening in manufacturing in southwestern Ontario.