Manufacturing Performance and Production KPI’s

There are entire libraries and courses dedicated to the science of manufacturing performance which is designed to drive productivity. I have seen many companies implement strategic philosophies such as Kaizen, Hoshin Planning, Lean Manufacturing, Six Sigma, Total Quality Management and Continuous improvement to help improve processes, drive productivity and visibility illustrate to their customers competitive differentiation.

Each practice uses KPI’s to asses, analyze and track manufacturing processes and performance. Each practice is successful, not because it is better than what you are doing today, but because it is a system that people believe in and follow. ERP’s are systems as well but the big difference is that they collect information from the shop floor and display it managers, in real-time and in meaningful ways.

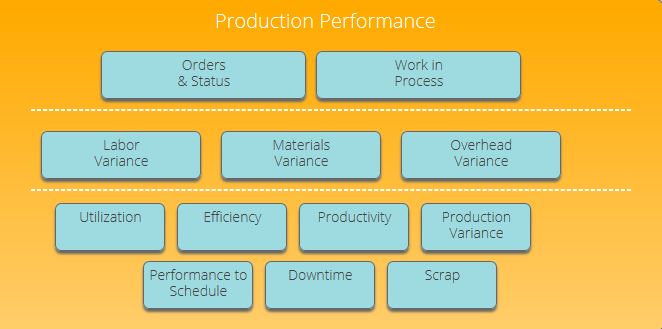

Below is an illustration of key performance indicators that Shop Floor’s need to look at and analyze.

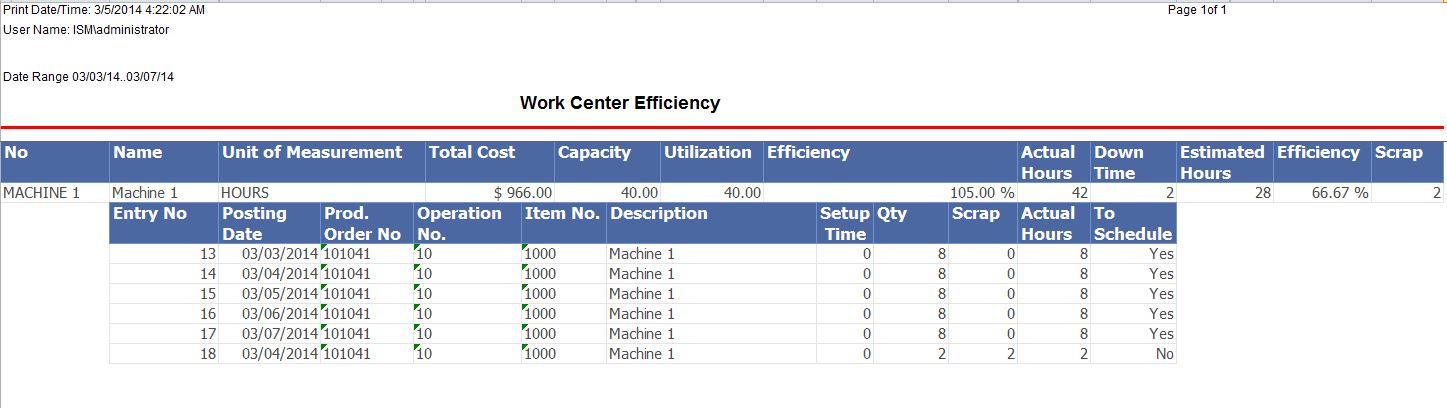

Dynamics NAV has the ability to track and monitor this information and the Vox Vertical Accelerator helps to display, meaningful information to the manager. This is an example of one such report that reports out the utilization, efficiency, production variance per operation, performance to schedule, downtime and scrap. It can be changed from the view of the work center to the employee for productivity.

This report was developed in the visual studio, so that it could be automatically emailed out.

This report was developed in the visual studio, so that it could be automatically emailed out.

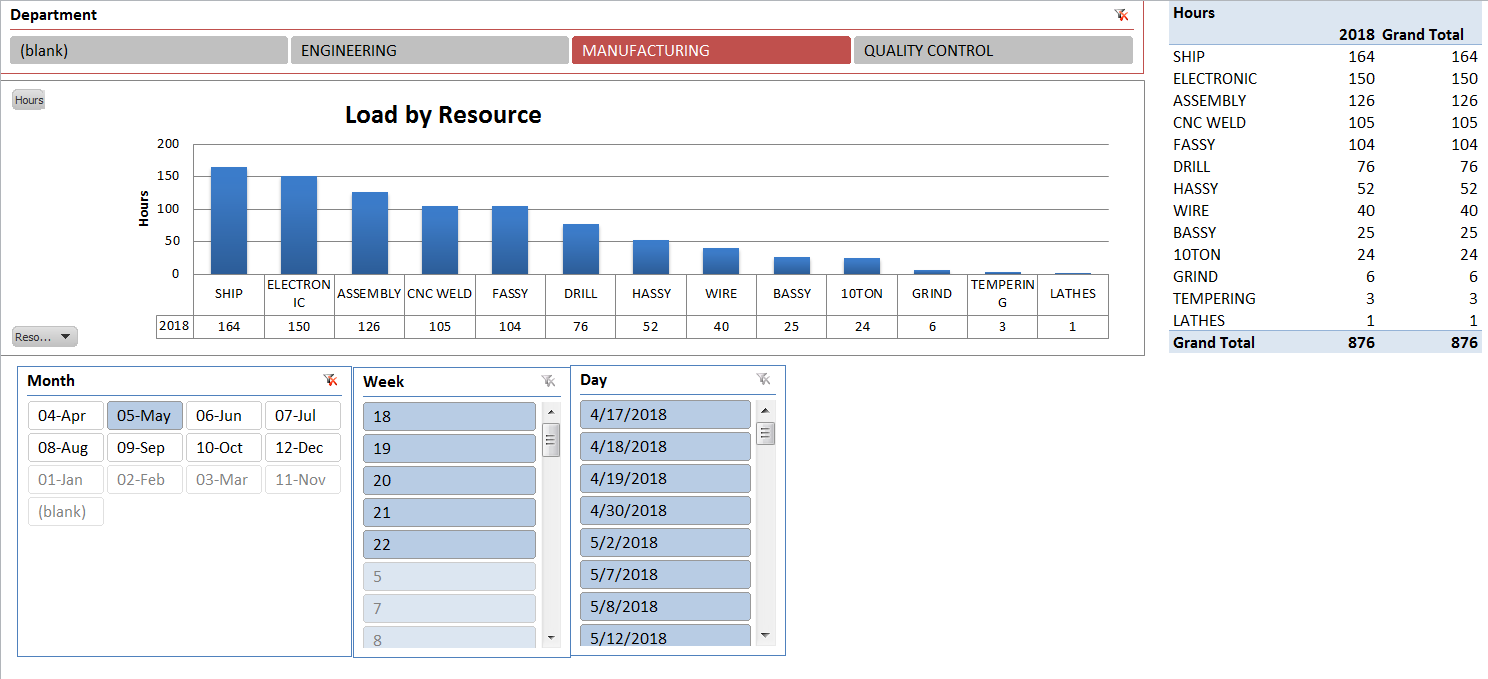

Then if required the managers can use the BI analytics to click and drill down through the detail and re-organize in excel.

Typically production managers are incented to increase productivity on the shop floor and so although these reports are good, they may not be good for the company as a whole. To keep the production manager in check you need to run these other reports.

Total Cost – as in its no good to have a production manager work overtime when it’s not necessary or when it drives costs higher than planned costs.

Total cycle time or Takt time – Estimators rely on production data so they can quote more accurately. Measuring and monitoring the operation’s time for a given part or part range over time is required.

Delivery Performance – you can keep the machines busy to make the reports look good but if you building work in process and not delivery to customers, this isn’t good.

Quality – there are several measurements you manage with the Dynamics business system. My favorite is customer complaints and returns

Safety – Making money safely is important if you want to keep good employees.

In conclusion, if you own a manufacturing company and want better systems and controls, you could implement a lean strategy, but I believe lean systems can work together with ERP systems.

Lean systems give clear visual signals and organization to dis-organized shops, but ERP systems make it much easier to use information that is collected. Furthermore, lean systems are ‘near-sighted’. They are not very good at modelling different scenario’s, analyzing data or projecting into the future.

Hopefully this article has explained what you need to run a successful manufacturing company. If this article was interesting then please sign up for one of our upcoming webinars that we host weekly to find out more.

Thanks

Mike Fontaine

March 13 2014