MRP and MPS in Business Central

Having a successfully executed and maintained manufacturing planning and control system can give companies a tremendous competitive advantage as it permits them to have highly accurate decisions, which accelerate the speed and accuracy of the response times.

Microsoft Dynamics 365 Business Central has great system planning capacities and functions which permits you to give answers to very relevant questions such as:

- How much material needs to be produced/bought to cover demand?

- What are the available and projected capacities for production?

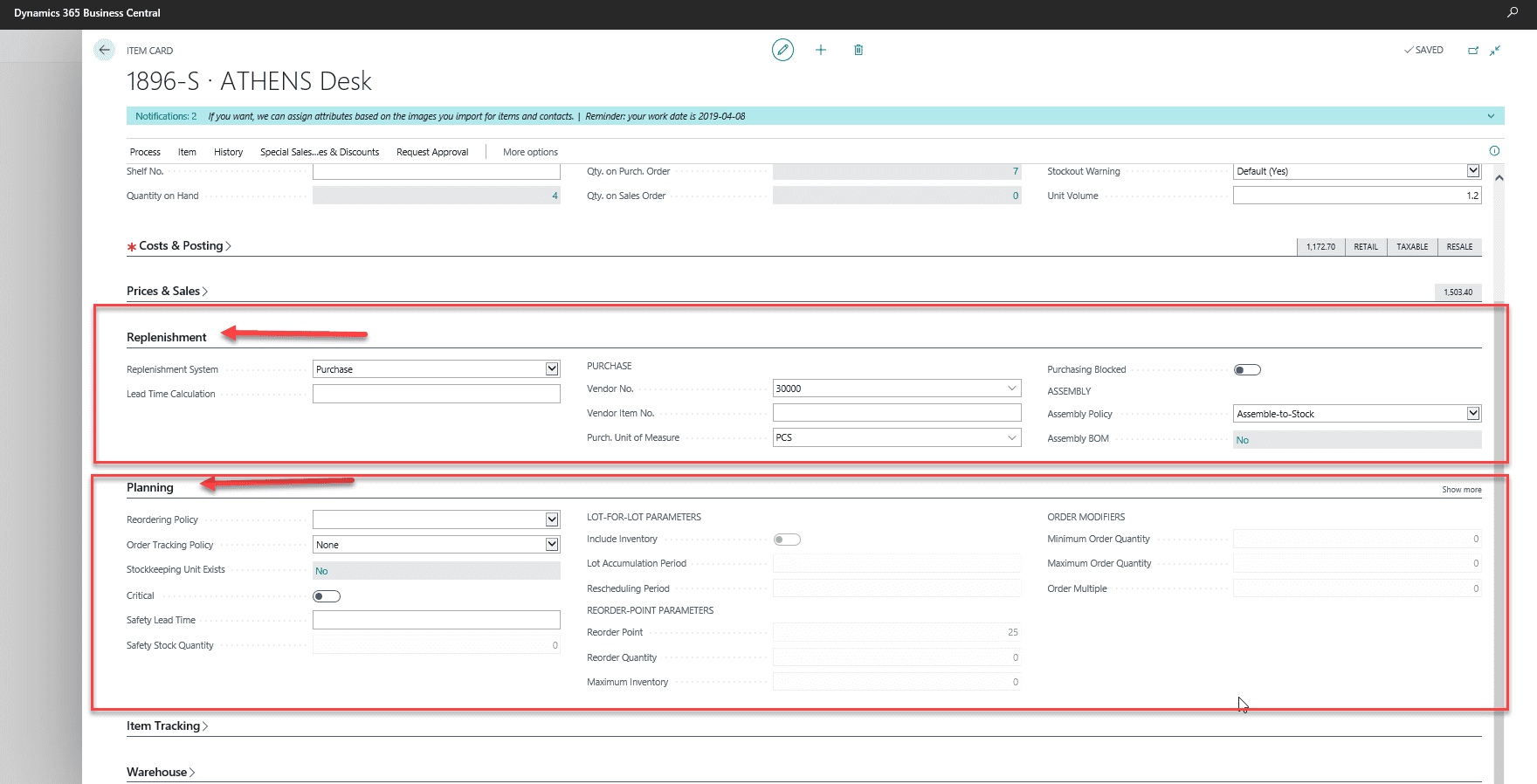

For each of your products (“items” in Business Central), you can set up parameters to define their replenishment and planning policies, which includes: replenishment methods (purchase, assembly, production/work orders), mins and maxes, a lot for lot, or automatic order reservations.

See below image – Part of the ‘Item master Card.’

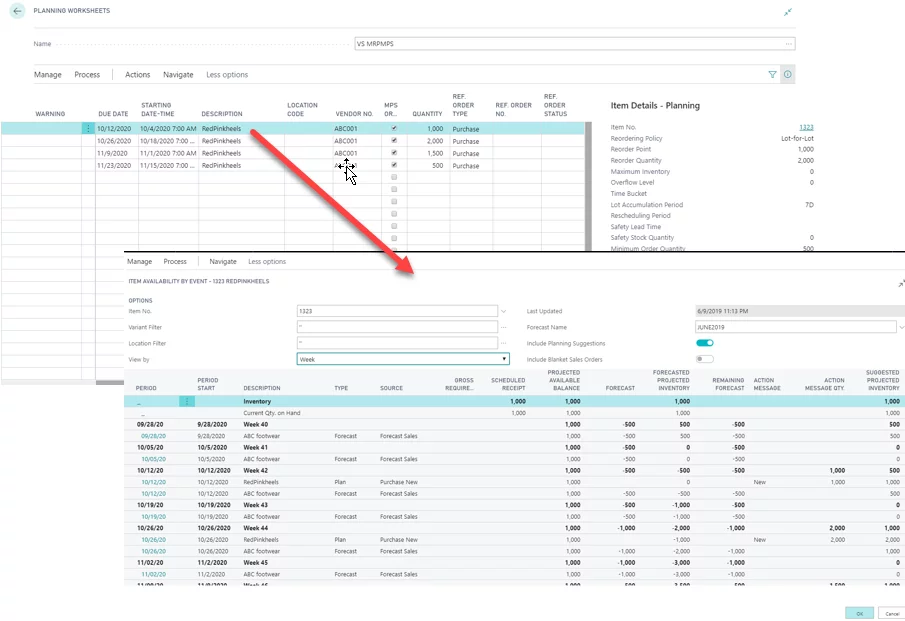

This extends as well into the components needed for your finished goods. The system will take into account the external and internal demands coming from sales orders, shipment dates, promised/requested delivery dates and work orders related (called “Production Orders” in Business Central) as well as from jobs/customized projects. Below and example when running the planning worksheet functionality and having a look at the Item availability by event.

Having a clear understanding of the demand events that will trigger the purchase or production of goods, as well as the possibility of Forecast application for seasonal businesses makes of Business Central a great ERP software to help with your company’s Sales & Operational plan.

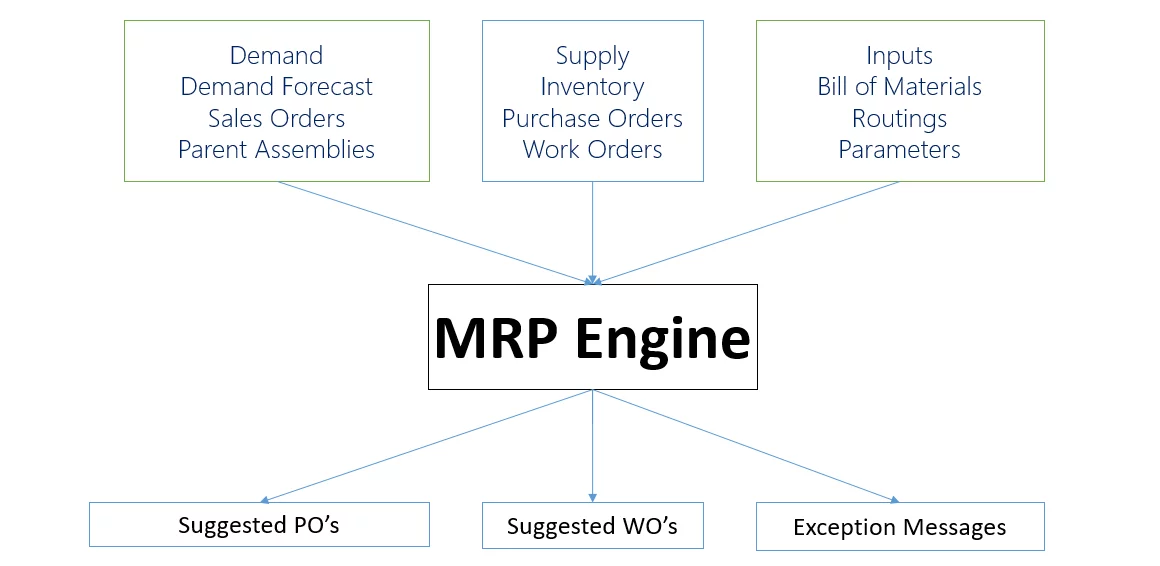

Having the demand and supply envisioned and clear, feeds the master production schedule, for the needed units of time of planning.

The system will take into account the capacity of your people, machines and workstations (called machine and work centers in Business Central) to cover the needed demand.

After this is established, the system logic goes deeper into the MRP level. It uses the scheduled receipt, demand events, bill of materials coming from the finished goods needed to be built and send out suggestions, so your production/planning team knows which components and when to get them, and for which vendor.

A significant function Business Central has, is also Canceling, or Rescheduling of orders, obeying to the always real-time- changing past and new demand and supply events.

In order to have a successfully implemented planning system in Business Central, you need to:

- Have all Finished Goods, their BOM and Routing, and additional planning setup complete as per your company policies.

- Remember to populate the Replenishment and Planning Fasttab of the item master card. These indicate the system the planning parameters logic your company needs.

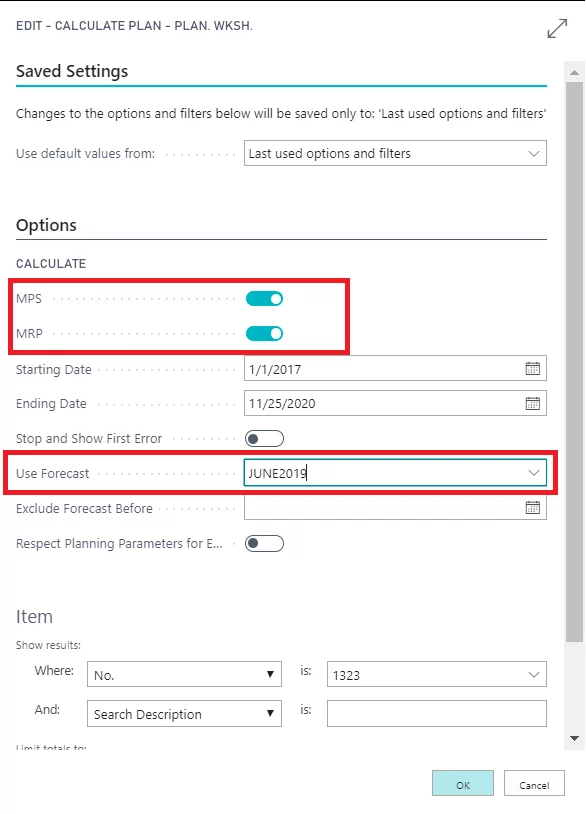

- Prepare and apply the Forecast codes to the planning worksheet generated plans. Apply this, especially when you have a seasonal business.

It is essential to set up for the very start accurate parameters, have many testing scenarios, so your team fully understands the available tools. Also, it will help them to know the best way to obtain and apply system information to make proactive decisions, correct and modify orders if necessary.

Learn more about MRP and MPS in Business Central

Join our exclusive webinar – Guide to Successful MRP and MPS in Business Central webinar

on March 11 at 1:30 PM (ET).

Blog post by David Morales – Financial Business Central Consultant

David Morales is a Microsoft Certified Professional (MCP), certified in Microsoft Dynamics Core Setup & Finance. Graduated from UNAB University’s Duale-Hochschule (Bsc) Business Administration program and Management Specialization Degree.