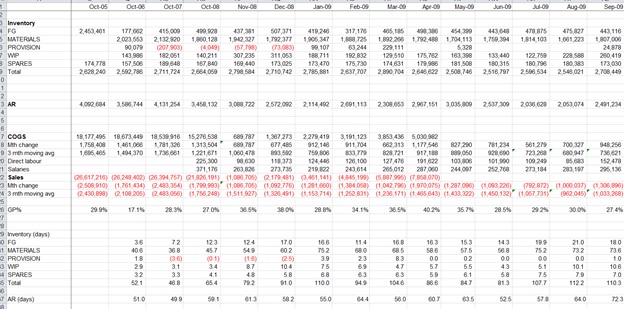

Examples of Management Reports that provide visibility of the business

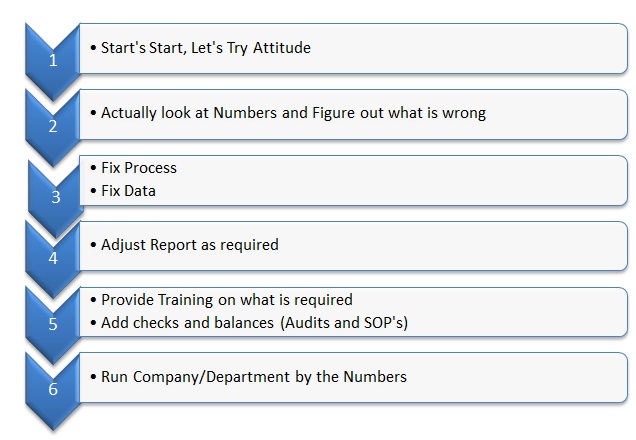

Overall Process to Run Company by the Numbers in 1 Month a step by step approach

Process per report

- Send out SSRS Daily Reports (What has happened and what will happen)

- Deploy and provide training on the excel spreadsheet (Analysis if there is a question)

- Next week – everyone who is on the distribution list, reviews and provides comments, this is done for the next 2 weeks (Trylon distribution list)

- Font changed

- I want just Field Service, etc

- I want with Tax, without Tax, etc

- Tabs in the spreadsheet will be made to accommodate the report variations (to provide drill down analysis for the user)

- Process Issues will be assigned with an action plan to resolve

- Data issues will be assigned with an action plan to resolve (same as above)

- Technical work – additional views, fields, etc will be added as required

- Audits will be created to keep process in check

- Audits measured by managers

- The daily/weekly reports will be refined/tweaked and distributed out to a larger group

- Standard Operating Procedure created, staff trained and discipline enforced

Inventory Audits

It is essential that negative inventories be corrected

to ensure proper material planning and inventory costing.

Negative Qty = MRP will suggest to purchase more and distort FIFO layers taking

costs from part maintenance not actuals

Negative Location = Timing problems with issues and receipts, incorrect

inventory records or issuing wrong part from wrong location. Also these

locations do not appear on hand held scanners for pickers so they never look

Adjustments = Monitor this number. Adjustments into inventory use standard cost

and by-pass revaulation. Typically the items are found later resulting in

corrections downstream. Currently this represents last 30 days.

Work Order Audits

You cannot achieve inventory accuracy or rely on

supply chain information without managing the transactions on work orders

Over Received Work Orders = Potentially pulled too much inventory from WIP if

backflushed or added too many FG to inventory.

Under Received = Opposite Problem to over, inventory will still be appear

available for other orders

Old Orders = Will continue to drive demand and supply in MRP and continue to

generate numbers for WIP

Unissued or Over Issued Material = potentially transaction mistakes,

substitutions or errors in scrap reporting.

Items appear on the list can be resolved by entering the proper quantity or

reason into user_5 on the work order

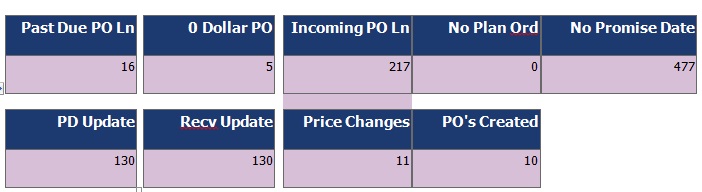

Purchasing Audits

You cannot achieve rely on supply chain information without managing the dates on purchase orders

You cannot achieve rely on supply chain information without managing the dates on purchase orders

Past Due PO = Do not have past due purchase orders, scheduling will assume they can build, old po’s will not prompt mrp to generate a new order

0 Dollar PO = 0 Dollar purchase orders if received will not accurate report inventory value or purchase order accuruals

Incoming Purchase Orders = Verify the accuracy of the inbound po’s, especialy if they are required for production

No Planned Orders = if you forgot to set an material planning policy and the part is required it will appear on this list

Promise Date on the purchase order line item is used to evaluate the vendor’s performance, no date means you might be evaulating him correctly.

Part of the process for planning is ensuring tha tthe dates are accurate, Audits have been activated on promise date and recv’d date fields to track activity

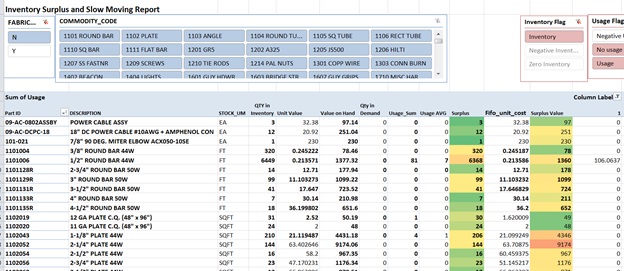

Running the company by the numbers is different than BI

This is an example of a BI report

This slow moving inventory report – it has many analytical purposes

a) it is used to figure out if you can substitute slow moving material in upcoming designs

b) Stop/cancel any outstanding purchase orders

c) Review historical demand and establish blanket orders for high moving

d) Establish safety stocks or months/weeks of supply or reduce if that is the problem

e) Review customer ordering in comparison to stocking, sometimes price breaks influence