Join us in person, or online, for the Windsor Microsoft Dynamics presentation and User Group Meeting on February 27th from 1:30 to 4:00 PM where we will demonstrate the modifications we have done on Microsoft Dynamics NAV to support the manufacturing industries in Southwestern Ontario.

Microsoft Product Partners and Vox ISM staff will be on-hand to answer all of your questions and teach you how to increase productivity and capacity with real-time access and visibility to data.

We have developed a complete business solution to meet the needs of manufacturing businesses based here in Ontario. Our integrated solution using Microsoft Dynamics CRM and Microsoft Dynamics NAV with our Vox ISM Vertical Accelerator reduces implementation time and cost which means our customers are up and running with less risk to them. What differentiates us from our competitors is our constant attention to our base customers through direct contact, User Group Meetings, and training webinars.

We have gone one step further and have tailored the Microsoft Dynamics NAV 2015 ERP system specifically for the automotive stamping, mold and injection molding industry in Southwest Ontario. This will provide a systematic approach to manage your jobs dramatically by improving your efficiency, productivity and profitability.

Rebirth of Oldcastle Ontario

Three of our new customers are blocks away from each other in Oldcastle Ontario. This town is the tool and die center of Ontario and supports the automotive industry in Detroit. Everywhere you go now in Oldcastle the parking lots are full and manufacturing is booming and capacity is low.

We know old technology can have many businesses feeling unprepared to keep-up with increased production demands. Luckily for southern Ontario manufactures, the Yves Landry AIME and CME SMART funding are back. And we can help you with application so you can take advantage of these programs so your business can adopt new technologies and improve your competitiveness.

“Since the financial collapse of 2008, the companies that survived have retooled and refocused on creating increasingly sophisticated component parts and molds and are leading a manufacturing comeback,” says Robert Cattle, executive director, Canadian Tooling and Machining Association

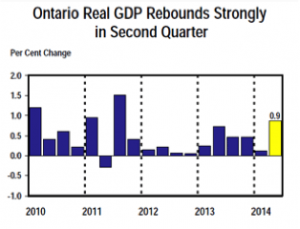

Capital Spending

Business capital spending in Ontario and the United States of the US on machinery and equipment has increased dramatically. Many of our latest customers make industrial equipment. As business spending on machinery grew and the US dollar went up they had a great year and were looking for a software solution that could handle the complexity of designing product, manufacturing and installation

Business capital spending in Ontario and the United States of the US on machinery and equipment has increased dramatically. Many of our latest customers make industrial equipment. As business spending on machinery grew and the US dollar went up they had a great year and were looking for a software solution that could handle the complexity of designing product, manufacturing and installation

Windsor | Microsoft Dynamics Presentation and User Group Meeting

WHEN: February 27th, 1:30 – 4:30PM

WHERE: Ciociaro Club | 3745 North Talbot Road, Oldcastle, ON N0R 1L0

REGISTER HERE

AGENDA

Software for Mold Shops

From estimating to tryout, Vox ISM supports you with proven industry standard practices to deal with the challenges you face every day. We’ll demonstrate how others in your industry are improving their sales, managing job documentation, communication and progress with their customers, integrating the BOM’s with CAD software, managing the crib inventory, subcontractors and scheduling the CNC’s, gun drilling and mold making departments. The accounting software handles progress payments, milestones, holdbacks and the management reporting provides three sets of numbers – how you quoted, designed and made the mold for job-by-job profitability. We know your industry and have been implementing in the Windsor and Oldcastle area for many years. Come see us and benchmark yourself against the competition, see how new technology can improve your business and provide value to your customers.

Software for Injection Molding

Are you TS certified but don’t have an integrated quality system? Are you having trouble tracking quality information, lot and batch? Do you need a shop floor barcoding system that generates labels real-time or is directly integrated to the extruders? Do you need to know how many shots go into the family mold, the cycle-time, scrap and costs per part? What about EDI, is your system complaint? Can you load in sales forecasts or calculate from history? Do you have blanket orders or purchasing contracts? Do you need to manage Gaylord’s, silo’s, railcars and convert seamlessly between LBS and KGS? If the answer is yes, come see what modern technology can bring to the table and how it can reduce your inventory, provide better product line profitability and reduce costs. Our system is affordable and tailored to your industry.

Software for Automotive Stamping

There are lots of automotive packages on the market, they do a good job but struggle to keep up with the pace of change in the automotive industry. Aggressive schedules, increasingly complex components, globalization, and cost challenges require a solution that is innovative and agile. From original equipment manufacturers to aftermarket parts suppliers, Vox ISM helps customers manage the demands of a modern automotive business with capabilities designed to meet the unique requirements of all industry segments. Manage the entire EDI-driven customer order and release update cycle with trading partner agreements. Automatically communicate new orders and release schedules to your suppliers through our portals. Multi-level BOM’s no problem, co-products (making a left and right part) no problem, automatic translation to your customers part, UPC or competitors part … no problem. Come see our solution can improve your business and allow you to scale with the Big Three.

To register, please visit www.voxism.com or call us at 905-840-7477